Identification of a nonlinear isotropic hardening rule#

In this demo, we use stress/plastic strain data of a steel material to show how to identify a nonlinear isotropic hardening rule with jaxmat.

Objectives

In particular, this demo shows:

How to define a trainable hardening rule based on an extended phenomenological expression

How to define a trainable hardening rule based on an Input-Convex Neural Network

How to train both models on a subset of noisy data

How to evaluate the models outside the training range

Loading and preprocessing experimental data#

We start by importing the necessary packages and loading experimental uniaxial stress–strain data from a steel sample. Data has been obtained from the X100 data used in the MEALOR “Simulation of ductile fracture models” lab session, see also [Besson et al., 2023]. The data represent the evolution of the yield stress as a function of equivalent plastic strain \(p\).

To test the robustness of our identification procedure, we artificially add a small amount of Gaussian noise to both the stress and plastic strain values. The noisy data are then sorted and truncated to define a training subset limited to \(p<5.10^{-2}\), leaving the rest for extrapolation.

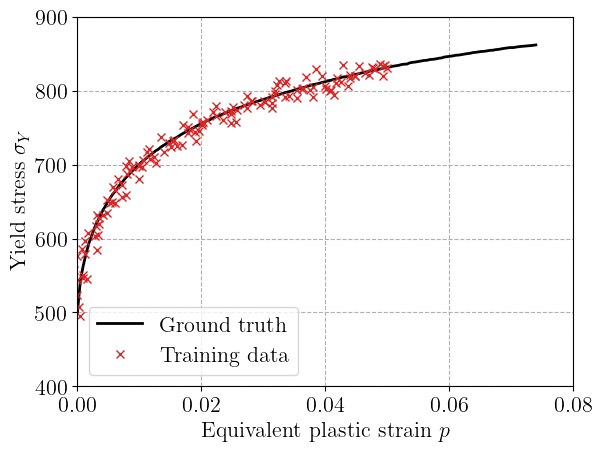

The plot below shows the ground-truth stress–strain curve and the noisy data used for training.

import jax

jax.config.update("jax_platform_name", "cpu")

import jax.numpy as jnp

from pathlib import Path

import matplotlib.pyplot as plt

import numpy as np

import equinox as eqx

import optimistix as optx

from jaxmat.nn.icnn import ICNN, ICNNSkip

current_path = Path().resolve()

data = np.loadtxt(current_path / "X100.csv", skiprows=1, delimiter=",")

epsp = data[:, 0]

sig = data[:, 1]

key = jax.random.key(42)

key1, key2 = jax.random.split(key)

noise_level = 0.01

sig_noise = sig + noise_level * max(sig) * jax.random.normal(key1, shape=(len(sig),))

epsp_noise = epsp + noise_level * max(epsp) * jax.random.normal(key2, shape=(len(sig),))

# sort and extract training region

indices = jnp.argsort(epsp_noise)[epsp_noise < 5e-2]

epsp_noise = epsp_noise[indices]

sig_noise = sig_noise[indices]

plt.figure()

plt.plot(epsp, sig, "-k", label="Ground truth")

plt.plot(epsp_noise, sig_noise, "xC3", linewidth=1, label="Training data")

plt.xlim(0, 8e-2)

plt.xlabel("Equivalent plastic strain $p$")

plt.ylabel(r"Yield stress $\sigma_Y$")

plt.legend()

plt.show()

<>:36: SyntaxWarning: "\s" is an invalid escape sequence. Such sequences will not work in the future. Did you mean "\\s"? A raw string is also an option.

<>:36: SyntaxWarning: "\s" is an invalid escape sequence. Such sequences will not work in the future. Did you mean "\\s"? A raw string is also an option.

/tmp/ipykernel_497987/2170504242.py:36: SyntaxWarning: "\s" is an invalid escape sequence. Such sequences will not work in the future. Did you mean "\\s"? A raw string is also an option.

plt.ylabel("Yield stress $\sigma_Y$")

Defining candidate hardening laws#

We now define two different models for the isotropic hardening law \(\sigma_Y(p)\):

Phenomenological Sum-Exponential Model: We consider an extended version of the Voce hardening law, where the yield stress saturates exponentially with plastic strain. We consider here a sum of \(N\) saturating exponentials written as:

\[\sigma_Y(p) = \sigma_0 + \sum_{i=1}^N \Delta\sigma_i \big(1 - \exp(-b_i p))\]where the parameters \(\sigma_0\), \(\Delta\sigma_i\), and \(b_i\) are learnable. Here \(\sigma_0\) denotes the initial yield stress and \(\sigma_0+\sum_i \Delta\sigma_i\) will correspond to the saturating stress.

Neural Network Model based on Input-Convex Neural Networks (ICNN): This model enforces convexity of the potential by construction, guaranteeing a monotonic hardening behavior. The yield stress is defined as the gradient of the convex potential output by the ICNN, see also Physics-Augmented Neural Networks for data-driven hyperelasticity.

Both models are implemented as equinox.Modules, allowing them to be handled as JAX PyTrees and trained with differentiable solvers.

class SumExpHardening(eqx.Module):

sig0: float = eqx.field(converter=jnp.asarray)

dsigu: jax.Array = eqx.field(converter=jnp.asarray)

b: jax.Array = eqx.field(converter=jnp.asarray)

def __call__(self, p):

return self.sig0 + jnp.sum(self.dsigu * (1 - jnp.exp(-self.b * p)))

N = 20

sumexp_hardening = SumExpHardening(

sig0=1000.0,

dsigu=jax.random.lognormal(key1, shape=(N,)),

b=jax.random.lognormal(key2, shape=(N,)),

)

class HardeningICNN(ICNN):

def __call__(self, p):

return jax.grad(super().__call__)(p)

icnn_hardening = HardeningICNN(0, [N], key)

Defining the loss function#

The training process minimizes a loss function that measures the mean squared error between the predicted yield stress \(\hat{\sigma}_Y(p)\) and the noisy data. To prevent overfitting and promote smoothness, we add an \(L^1\) regularization term on the model parameters:

where \(M\) is the number of data points, \(\gamma\) is a regularization coefficient and \(n_{\btheta}\) denotes the total number of parameters in \(\btheta\). Both the data loss and the regularization term are written in a fully JAX-compatible manner.

def loss(hardening, args):

epsp, sig = args

M = len(epsp)

sig_hat = jax.vmap(hardening)(epsp)

return jnp.sum((sig_hat - sig) ** 2) / M, sig_hat

def l1reg(hardening):

flat_params, _ = jax.flatten_util.ravel_pytree(eqx.filter(hardening, eqx.is_array))

return jnp.linalg.vector_norm(flat_params, ord=1) / len(flat_params)

@eqx.filter_jit

def total_loss(hardening, args):

data, gamma = args

data_loss, sig_hat = loss(hardening, data)

return data_loss + gamma * l1reg(hardening), sig_hat

Training procedure#

We use the quasi-Newton BFGS solver from the optimistix library to minimize the total loss. The BFGS algorithm is particularly well suited for small parameter sets and ensures fast convergence without the need for stochastic optimization.

Each hardening model (phenomenological and ICNN-based) is trained independently on the same noisy dataset.

During optimization, the solver adjusts the parameters to best reproduce the measured yield stress values. Thanks to JAX’s automatic differentiation, all gradients are computed exactly and efficiently.

Note that \(\gamma\) is a hyperparameter which must be tuned by chosen before hand by the user.

gamma = 0.1

solver = optx.BFGS(

rtol=1e-6,

atol=1e-8,

# verbose=frozenset({"loss", "step_size"})

)

training_data = (epsp_noise, sig_noise)

for hardening in [sumexp_hardening, icnn_hardening]:

sol = optx.minimise(

total_loss,

solver,

hardening,

args=(training_data, gamma),

has_aux=True,

throw=False,

max_steps=1000,

)

trained_hardening = sol.value

sig_hat = sol.aux

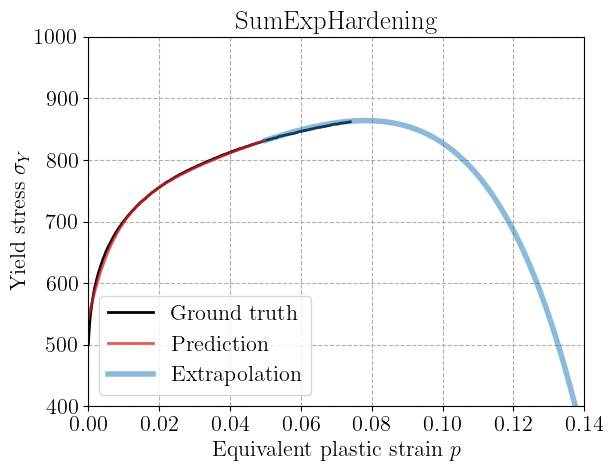

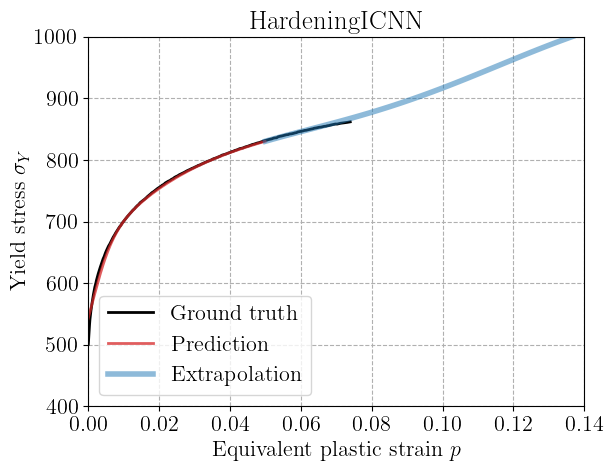

plt.figure()

plt.plot(epsp, sig, "-k", label="Ground truth")

plt.plot(epsp_noise, sig_hat, "-C3", alpha=0.75, label="Prediction")

epsp_extrap = jnp.linspace(5e-2, 14e-2, 100)

sig_extrap = jax.vmap(trained_hardening)(epsp_extrap)

plt.plot(

epsp_extrap, sig_extrap, "-C0", linewidth=4, alpha=0.5, label="Extrapolation"

)

plt.xlim(0, 14e-2)

plt.ylim(400, 1e3)

plt.xlabel("Equivalent plastic strain $p$")

plt.ylabel(r"Yield stress $\sigma_Y$")

plt.title(hardening.__class__.__name__)

plt.legend()

plt.show()

<>:34: SyntaxWarning: "\s" is an invalid escape sequence. Such sequences will not work in the future. Did you mean "\\s"? A raw string is also an option.

<>:34: SyntaxWarning: "\s" is an invalid escape sequence. Such sequences will not work in the future. Did you mean "\\s"? A raw string is also an option.

/tmp/ipykernel_497987/1942242727.py:34: SyntaxWarning: "\s" is an invalid escape sequence. Such sequences will not work in the future. Did you mean "\\s"? A raw string is also an option.

plt.ylabel("Yield stress $\sigma_Y$")

Results and extrapolation#

After training, we visualize the predicted hardening curves along with the experimental data. The solid black line shows the ground truth, red crosses the noisy training data,

We also evaluate the models beyond the training range (\(p > 5.10^{-2}\)) in blue to test their extrapolation capability. This is important for constitutive modeling since we often need to predict material behavior beyond the calibrated strain range.

Typically, the phenomenological SumExp model performs well within the training range but may struggle when generalizing outside the training region. We can check that tuning the hyperparameter \(\gamma\) or increasing the number of terms does not yield much better results. In this case, it is preferable to use a relatively small number \(N\) of terms in the expansion.

Conversely, the ICNN-based model can learn more flexible shapes while still guaranteeing monotonic hardening, thanks to its convexity constraint. As a result, it performs relatively well outside the training range in general.

References#

Jacques Besson, Jérémy Bleyer, Sylvia Feld-Payet, Anne-Françoise Gourgues-Lorenzon, Florent Hannard, Thomas Helfer, Jeremy Hure, Djimedo Kondo, Veronique Lazarus, Christophe Le Bourlot, and others. Mealor ii damage mechanics and local approach to fracture. 2023.