Modified Cam-Clay#

In this example, we implement and solve a Modified Cam-Clay (MCC) model using the jaxmat library.

Objectives

The goal of this demo is to illustrate how to:

Define an elasto-plastic constitutive model with mixed isotropic–kinematic hardening.

Integrate the constitutive equations by solving an implicit system with plastic consistency conditions.

Evaluate the model response for non-proportional load paths.

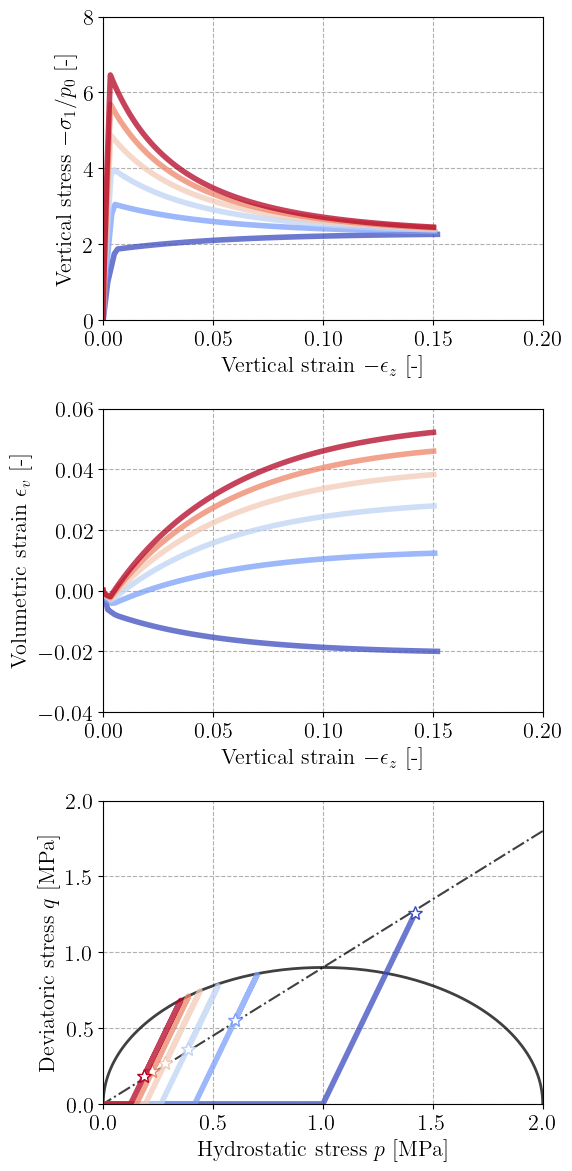

The workflow follows the same structure as in the Green viscoplastic model demo: we successively define the internal variables, the yield surface, the hardening law, and the constitutive update. We then simulate several over-consolidation ratios (OCRs) to study the material’s transition from contractant to dilatant behavior.

Model overview#

The Modified Cam-Clay (MCC) yield function is defined as:

where

\(p = -\frac{1}{3}\,\tr(\bsig)\) is the mean pressure,

\(q = \sqrt{\frac{3}{2}\bs:\bs}\) is the von Mises equivalent stress,

\(M\) is a material parameter describing the critical state line slope in the \((p,q)\) plane

\(p_c\) is a hardening variable called critical pressure (\(2pc\) is the preconsolidation pressure).

Usually, we assume that the material possesses no tensile strength so that the yield surface lies only within the compressive stress region. This implies that the yield criterion is expressed as:

The preconsolidation pressure evolves with volumetric plastic strain \(\varepsilon_v = \mathrm{tr}(\bepsp)\) according to the exponential hardening law:

where \(p_{c0}\) is the initial critical pressure and \(\beta\) is a hardening rate coefficient.

Attention

The Modified Cam-Clay model exhibits mixed hardening: the yield ellipse translates along the hydrostatic axis (kinematic part) and expands or contracts (isotropic part). During compression (\(\varepsilon_v < 0\)), the material hardens as \(p_c\) increases; during dilation (\(\varepsilon_v > 0\)), it softens. This coupling naturally captures the contractant–dilatant transition observed in soils near the critical state.

Model implementation#

We now proceed to implement the model step by step with jaxmat.

import jax

import jax.numpy as jnp

jax.config.update("jax_platform_name", "cpu")

import jaxmat

import jaxmat.materials as jm

from jaxmat.tensors import SymmetricTensor2, dev, safe_sqrt

from jaxmat.tensors.utils import FischerBurmeister as FB

from jaxmat.loader import ImposedLoading, global_solve

import equinox as eqx

import optimistix as optx

from optax.tree_utils import tree_zeros_like

import matplotlib.pyplot as plt

We import the relevant jax and jaxmat modules, enabling automatic differentiation, batched tensor operations, and root-finding through optimistix. The Fischer–Burmeister (FB) function will be used to impose the Kuhn–Tucker complementarity conditions of plasticity in a (semi-)smooth way.

Internal state definition#

The internal variable for the Modified Cam-Clay model is the plastic strain tensor \(\bepsp\).

We define a small subclass of AbstractState to store and update this tensor between time steps.

# Define internal state to store plastic strain

class InternalState(jaxmat.state.AbstractState):

epsp: SymmetricTensor2 = eqx.field(default_factory=lambda: SymmetricTensor2())

Yield surface#

We now define the Cam-Clay yield surface. The class inherits from AbstractPlasticSurface and thus automatically computes the normal vector to the yield surface via its normal method. We simply need to implement the expression of the yield surface in the __call__ dunder method. We decorate the latter with the safe_zero decorator as described in the Norton viscoplastic model with a Green yield surface demo.

class CamClaySurface(jm.AbstractPlasticSurface):

M: float = eqx.field(converter=jnp.asarray) # critical state line parameter

@jm.safe_zero

def __call__(self, sig, pc):

p = -jnp.trace(sig) / 3

s = dev(sig)

q2 = 3.0 / 2.0 * jnp.vdot(s, s)

return safe_sqrt((pc - p) ** 2 + q2 / self.M**2)

Hardening law#

We next define the exponential hardening rule for the preconsolidation pressure:

class Hardening(eqx.Module):

beta: float = eqx.field(converter=jnp.asarray)

pc0: float = eqx.field(converter=jnp.asarray)

def __call__(self, ep):

return self.pc0 * jnp.exp(-self.beta * ep)

The function takes the volumetric plastic strain \(\varepsilon_v\) as input and returns the corresponding \(p_c\).

Constitutive update#

We now assemble all components into the main Modified Cam-Clay class. This class inherits from SmallStrainBehavior and defines the local integration algorithm to update the stress and state variables implicitly as follows:

The constitutive update proceeds first by defining the final stress expression from the known strain increment \(\Delta\beps\) and the unknown plastic strain increment \(\Delta\bepsp\).

The residual system enforcing the plastic flow rule and yield condition is then defined. Note that although the plastic multiplier increment \(\Delta\lambda\) has not been defined as a state variable, it is an auxiliary unknown that we need to solve for. Moreover, we use the Fischer–Burmeister function FB(x,y) (see Fischer-Burmeister functions) to smoothly impose the complementarity condition between plastic consistency and plastic multiplier. The discretized system using an implicit Euler scheme is here to find \((\Delta\lambda,\Delta\bepsp)\) such that:

where \(\varepsilon^\text{p}_v = \varepsilon^\text{p}_{v,n} + \Delta \varepsilon^\text{p}_v\) and where the last line is equivalent to:

We solve the nonlinear system with optimistix.root_find, using automatic differentiation for the Jacobian and finally return the updated stress \(\bsig\) and internal variable \(\bepsp\).

class ModifiedCamClay(jm.SmallStrainBehavior):

elasticity: jm.LinearElasticIsotropic

plastic_surface: CamClaySurface

hardening: Hardening

internal_type = InternalState

@eqx.filter_jit

@eqx.debug.assert_max_traces(max_traces=1)

def constitutive_update(self, eps, state, dt):

eps_old = state.strain

deps = eps - eps_old

isv_old = state.internal

epsp_old = isv_old.epsp

sig_old = state.stress

def eval_stress(deps, depsp):

return sig_old + self.elasticity.C @ (deps - depsp)

def solve_state(deps, epsp_old):

def residual(dy, args):

dlamb, depsp = dy

sig = eval_stress(deps, depsp)

epsp = epsp_old + depsp

epspv = jnp.trace(epsp)

pc = self.hardening(epspv)

yield_criterion = self.plastic_surface(sig, pc) - pc

n = self.plastic_surface.normal(sig, pc)

res = (depsp - dlamb * n), FB(-yield_criterion, dlamb)

return (res, epsp)

sol = optx.root_find(

residual,

self.solver,

y0=(0.0, tree_zeros_like(epsp_old)),

has_aux=True,

adjoint=self.adjoint,

)

dlamb, depsp = sol.value

epsp = sol.aux

sig = eval_stress(deps, depsp)

return sig, epsp

sig, epsp = solve_state(deps, epsp_old)

isv = isv_old.update(epsp=epsp)

new_state = state.update(strain=eps, stress=sig, internal=isv)

return sig, new_state

Evaluating the model#

We instantiate below the MCC material by choosing \(M=0.9\) and \(\beta=30\), corresponding to typical clay parameters. The initial critical pressure is chosen here to be \(p_{c0}=1\text{ MPa}\).

elasticity = jm.LinearElasticIsotropic(E=248.28, nu=0.241)

cc_surface = CamClaySurface(M=0.9)

pc0 = 1.0

hardening = Hardening(pc0=pc0, beta=30.0)

material = ModifiedCamClay(

elasticity=elasticity, hardening=hardening, plastic_surface=cc_surface

)

Load cases and initialization#

We prepare a set of load cases corresponding to a triaxial compression test. In a first phase, for \(0 \leq t\leq t_\text{cons}\), we define an isotropic consolidation load case, until reaching linearly with time a consolidation pressure \(p_0\). The ratio \(\text{OCR}=2p_{c0}/p_0\) defines the so-called Over-Consolidation Ratio (OCR). For each OCR, the end of the consolidation phase results in a hydrostatic strain state \(\beps = -p_0/(3\kappa) \bI\) where \(\kappa\) is the material bulk modulus. In total, we define six different OCRs from 2 to 16. Each case represents a different initial consolidation level: over-consolidated clays (large OCR) are stiffer and tend to dilate under shear, while normally consolidated clays (low OCR) tend to contract.

After this consolidation phase, we further increase the vertical compressive strain \(-\varepsilon_{zz}\) while maintaining the lateral confining pressure, i.e. \(\sigma_{xx}=\sigma_{yy}=-p_0\).

All 6 OCR load cases are integrated simultaneously as a batched simulation.

def compute_pq(sig):

p = -jnp.trace(sig) / 3

s = dev(sig)

q = jnp.sqrt(3.0 / 2.0 * jnp.vdot(s, s))

return p, q

OCR = jnp.linspace(2, 16, 6)

Nbatch = len(OCR)

p0_vals = 2 * pc0 / OCR

state = material.init_state(Nbatch)

eps_dot = 15e-2

Nsteps = 121

t_cons = 0.2

times = jnp.linspace(0, 1.2, Nsteps)

t = 0

imposed_eps = p0_vals / 3 / elasticity.kappa

p, q = jax.vmap(compute_pq)(state.stress)

results = jnp.zeros((Nsteps, Nbatch, 5))

for i, dt in enumerate(jnp.diff(times)):

t += dt

if t <= t_cons:

pcons = p0_vals * t / t_cons

loading = ImposedLoading(sigxx=-pcons, sigyy=-pcons, sigzz=-pcons)

else:

imposed_eps += eps_dot * dt

loading = ImposedLoading(epszz=-imposed_eps, sigxx=-p0_vals, sigyy=-p0_vals)

Eps = state.strain

Eps, state, stats = global_solve(Eps, state, loading, material, dt)

Sig = state.stress

p, q = jax.vmap(compute_pq)(Sig)

results = results.at[i + 1, :, 0].set(-Eps[:, 2, 2])

results = results.at[i + 1, :, 1].set(jnp.trace(Eps, axis1=2))

results = results.at[i + 1, :, 2].set(-Sig[:, 2, 2])

results = results.at[i + 1, :, 3].set(p)

results = results.at[i + 1, :, 4].set(q)

Finally, we plot the corresponding stress and strain evolutions for the different OCR. The first plot shows the vertical stress/strain curve where we can clearly observe softening for the over-consolidated cases and hardening otherwise. The second plot shows the typical transition between contractance and dilatance during the softening evolutions. Finally, the last plot represents the stress paths in the \((p,q)\) space. The star symbols denote the final stress state for each cases which all fall on the critical state line of equation \(q=Mp\).