Computing the Hosford plane stress yield surface#

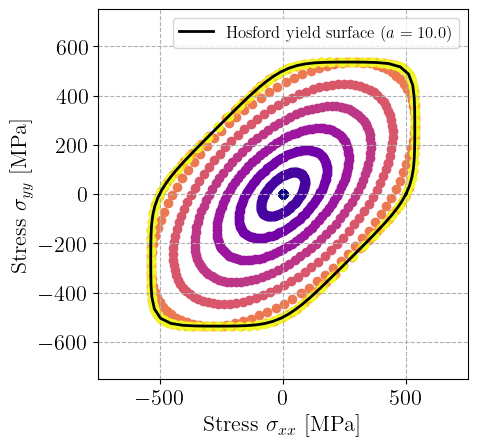

This short demo shows how to define a perfectly plastic material associated with the Hosford equivalent stress and how to compute its yield surface in plane stress conditions.\(\newcommand{\bsig}{\boldsymbol{\sigma}}\newcommand{\beps}{\boldsymbol{\varepsilon}}\)

See also

This demo is inspired by the MFront Hosford tutorial.

The Hosford yield surface is defined by:

where \(\sigma_\text{eq}^\text{H}\) is the Hosford equivalent stress associated with the shape parameter \(a\). For \(a=2\), this reduces to the von Mises norm and, for \(a\to\infty\), we obtain the Tresca norm.

We first define a GeneralIsotropicHardening JAX material without any hardening.

import numpy as np

import matplotlib.pyplot as plt

from dolfinx_materials.jax_materials import (

GeneralIsotropicHardening,

LinearElasticIsotropic,

Hosford_stress,

)

import jax

plt.ioff()

E = 70e3

nu = 0.3

elastic_model = LinearElasticIsotropic(E, nu)

a = 10.0

sig0 = 500.0

material = GeneralIsotropicHardening(

elastic_model, lambda p: sig0, lambda sig: Hosford_stress(sig, a=a)

)

An NVIDIA GPU may be present on this machine, but a CUDA-enabled jaxlib is not installed. Falling back to cpu.

We want to plot the corresponding yield surface in the plane stress domain \((\sigma_{xx}, \sigma_{yy}, \sigma_{zz}=0)\). We generate Nbatch strain loading directions in the \((\varepsilon_{xx},\varepsilon_{yy})\) plane and we will increment the strain proportionally up to a maximum value \(\varepsilon_{max}=10^{-2}\).

eps = 1e-2

Nbatch = 100

theta = np.linspace(0, 2 * np.pi, Nbatch)

Eps = np.vstack(

[np.array([eps * np.cos(t), eps * np.sin(t), 0, 0, 0, 0]) for t in theta]

)

material.set_data_manager(Eps.shape[0])

state = material.get_initial_state_dict()

Since the constitutive equation is strain-driven, we need to adjust the out-of-plane strain \(\varepsilon_{zz}\) to satisfy the plane stress condition \(\sigma_{zz}=0\). To do so, we will apply an additional Newton method after each computation to enforce \(\sigma_{zz}=0\). This Newton step amounts to find the out-of-plane strain correction \(\delta\varepsilon_{zz}\) such that:

Hence, the Newton correction step involves the out-of-plane component \(\mathbb{C}^\text{tang}_{zzzz}\) of the tangent operator and reads:

We benefit from JAX automatic vectorization by writing this correction step for a single load case and use jax.vmap to loop overall loading paths automatically.

def correct_epszz(eps, sig, Ct):

return (-sig[2]) / Ct[2, 2]

global_correct = jax.vmap(jax.jit(correct_epszz))

The tolerance of this plane stress correction will be measured by the out-of-plane stress residual \(|\sigma_{zz}/E|\). We define a tolerance tol=1e-6 and a maximum number of iterations. We then loop over each load step increment, compute the stress for \(\varepsilon_{zz}=0\) and then do the plane stress correction until converging. Finally, we plot the resulting distribution of stresses and compare against the analytical equation of the Hosford yield surface.

tol = 1e-6

niter_max = 20

depszz = np.zeros((Nbatch,))

times = np.linspace(0, 1.0, 10)

cmap = plt.get_cmap("plasma")

colors = cmap(times / max(times))

fig, ax = plt.subplots()

for i, t in enumerate(times):

print(f"Increment {i+1}/{len(times)}")

Eps_i = t * Eps

res_plane = np.ones((Nbatch,))

k = 0

while np.any(res_plane > tol) and k < niter_max:

sig, isv, Ct = material.integrate(Eps_i)

depszz = global_correct(Eps_i, sig, Ct)

Eps_i[:, 2] += depszz

res_plane = np.abs(sig[:, 2] / E)

k += 1

if k >= niter_max:

raise ValueError("Maximum number of iterations reached.")

material.data_manager.update()

ax.scatter(sig[:, 0], sig[:, 1], color=colors[i])

def normalize_by_Hosford(sig):

sig_eq = Hosford_stress(sig)

return sig * sig0 / sig_eq

sig_list = np.vstack([np.array([np.cos(t), np.sin(t), 0, 0, 0, 0]) for t in theta])

Sig = jax.vmap(normalize_by_Hosford)(sig_list)

ax.plot(Sig[:, 0], Sig[:, 1], "-k", label=rf"Hosford yield surface $(a={a})$")

ax.set_xlabel(r"Stress $\sigma_{xx}$ [MPa]")

ax.set_ylabel(r"Stress $\sigma_{yy}$ [MPa]")

ax.legend(fontsize=12)

ax.set_xlim(-1.5 * sig0, 1.5 * sig0)

ax.set_ylim(-1.5 * sig0, 1.5 * sig0)

ax.set_aspect("equal")

plt.show()

Increment 1/10

Increment 2/10

Increment 3/10

Increment 4/10

Increment 5/10

Increment 6/10

Increment 7/10

Increment 8/10

Increment 9/10

Increment 10/10